-

Opening hours: 8AM - 6PM

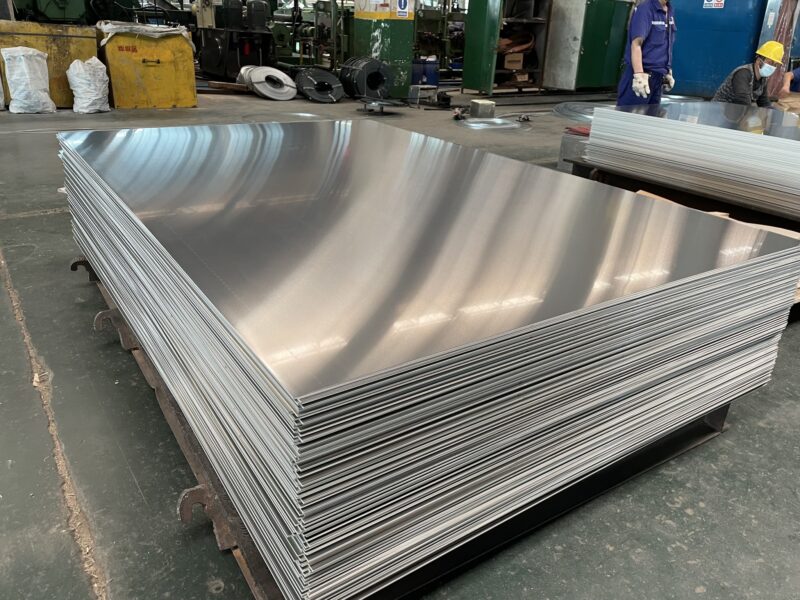

Aluminum Bar

Low MOQ and Flexible Production Ability

Payment: L/C, D/A, D/P, T/T, According to customer requirements

price terms:FOB, CRF, CIF, EXW all acceptable

Delivery: within 10-15 days or considering the quantity

Transport: By bulk or Containers

Support video inspection, welcome to visit our factory

SPECIFICATIONS

1100 (UNS A91100) is commercially pure aluminum (99.00% minimum). Excellent corrosion resistance, workability and weldability; high thermal conductivity. Tensile strength range 14,000 to 24,000 psi. Users include deep drawing, spinning, sheet metal work, decorative and architectural applications, air ducts, name plates, fan blades, etc. Conforms to Federal specification QQ-A-250/1 and ASTM B-209.

3003 (UNS A93003) is alloyed with 1.2% manganese to provide a tensilestrengthrangeof17,000to30,000psi.Excellentworkability, weldability and corrosion resistance. Used for drawing, spinning, fuel tanks, sheet metal work and other applications where slightly higher strength than 1100 is required. Conforms to Federal specification QQ-A-250/2 and ASTM B-209.

5052 (UNS A95052) is alloyed with 2.5% magnesium. Tensile strength range 31,000 to 44,000 psi. Very good corrosion resistance, good workability, weldability and strength. Used for aircraft fuel tanks, storm shutters, refrigerator liners, utensils, electronic mounting plates and panels, fan blades, etc. Conforms to Federal specification QQ-A-250/8 and ASTM B-209.

6061 (UNS A96061) is alloyed with 1.0% magnesium and .6% silicon.Tensile strength range 20,000 to 42,000 psi.Good formability, weldability and corrosion resistance. Used for engineering and structural applications, boats, furniture, transportation equipment, etc. Conforms to Federal specification QQ-A-250/11 and ASTM B-209

2024 (UNS A92024), is alloyed with 4.5% copper.Tensile strength range 30,000 to 63,000 psi. Fair weldability and corrosion resistance. Forming operations are limited. Used for high strength structural and aircraft applications. 2024 conforms to Federal specification QQ-A-250/4 and ASTM B-209.

Cast Plate (Aluminum Cast Machined Plate) is a general purpose cast tool and jig plate featuring many unique characteristics. It is a high-quality, accurately machined product that has received a thermal stress-relieving treatment to provide dimensional stability during machining.

7075 (UNS A97075) is heavily alloyed with zinc with lesser amounts of magnesium, copper and chromium. One of the strongest of the aluminum alloys, its use parallels that of 2024 with 7075 selected when higher mechanical properties are desired. Forming operations are limited. All 7075 flat products conform to ASTM B-209; 7075 Bare conforms to Federal specification QQ-A-250/12.

Reviews

There are no reviews yet.